I love knitting, particularly socks but I freely admit that I am not exactly an expert. I think, so far, I’ve probably knitted more socks than anything else – maybe a dozen pairs over the last few years.

I love the way they feel on your feet. They take a little getting used to if you normally wear shop bought cotton socks. They’re thicker and because of the way they’re constructed (ie knitted tubes) they can feel a little bumpy under your feet at first. But I find that after a few days of wear, they begin to smooth out and you get used to having that little bit of extra padding. And nothing is better in Winter then a pair of snuggly socks on your feet. I’ve not gotten a single blister from wearing my Winter boots and shoes since I started wearing handknitted socks.

The only problem is that they do wear out, especially if like me you wear them All. The. Time. I am also a complete heathen and tend to wear them on their own without shoes or slippers around the house which causes them to wear out even faster.

The first place most socks tend to wear out is the toe, just under your toes, the padded bit. It hits the ground constantly, causing friction and thus the wool/whatever wears faster than the rest of the sock. But toes are relatively easy to replace. You can darn them fairly easily. Or if you’re feeling particularly cunning, knit a new toe! Unpick the cast off end of the toe, unravel past the worn out place, put the live stitches back on the needles, knit a new toe. Ta-dah.

(No, I don’t have photos. Sorry. But trust me, it’s easy.)

The other place that ALL my socks wear out is the heel. Just underneath my heel to be precise. Always the left sock first, always in the same place.

Knitting your own socks is an interesting exercise in learning about how you tend to walk. I obviously put most of my weight on my heels and walk with an emphasis on my left foot.

But, I digress.

If you are smarter than me, you’ve probably long since figured out what I’m going to show you, or given up doing heel flap socks in favour of something fancy like an afterthought heel. But for us poor schmoes still beavering away on heel flaps and gussets, here is how I managed to knit a new heel on my very favourite pair of socks, thus saving them from the bin and preserving them to warm my toes for another winter, at least.

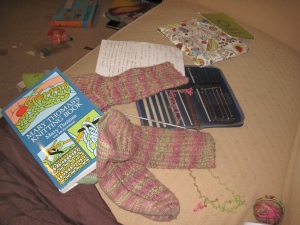

First thing you need to do is grab yourself a copy of Mary Thomas’s Knitting Book. My copy says first published in 1938, so you have to make allowances for style and some of the little cartoons in it are definitely.. of their time, shall we say? But the text is invaluable for its history of knitting, particularly with reference to the British Isles. Plus she has a wealth of technical information to impart. Including how to knit a wide variety of sock heels, and how to re-heel a worn out flap and gusset heel.

Second thing you will need is a small ball of wool, if possible leftovers from making your sock, if not, get something that will make a nice contrast. Remember, you are knitting a whole new heel, so you need enough to do about 40 – 50 rows of knitting, depending on the size of your heel flap. My heel flap worked out at about 36 rows, before I turned the heel.

You will also need a crochet hook and a set of 4 double pointed needles. And a blunt tapestry needle for grafting and darning in the ends of your wool. I used a set of 2.5 mm needles because that’s what I used when I knit the sock in the first place. (If you want your sock heel to last longer, using a smaller set of needles is a good idea as it makes for a tighter fabric, apparently.)

Step One

In the book she talks about cutting away the heel stitches completely, but I was too cowardly to do that. So instead, I grabbed a crochet hook and my ball of mending yarn and began picking up stitches at the place where the sock leg ends and the heel flap begins.

I made a long tail of yarn, which I threaded through to the inside of my sock, leaving the main ball on the outside.

This is REALLY important because otherwise when you finish picking up your stitches, your ball of working yarn will be trapped inside your sock, rendering it totally useless.

This is REALLY important because otherwise when you finish picking up your stitches, your ball of working yarn will be trapped inside your sock, rendering it totally useless.

Take your crochet hook and insert it into the first stitch in your heel flap.

Wrap the tail of yarn around to make a stich and pull the stitch back through, making a loop on the crochet hook.

Leave the loop on there, and move onto the next stitch in the heel flap. Repeat until you have a nice neat row of loops on your crochet hook.

These will become the stitches for your new heel flap. You want to try to match the number of stitches in your original heel flap, if possible. I ended up with 38 stitches which seemed to match up with the measurements of my original heel flap.

Now, transfer the stitches from your crochet hook to a DPN:

You now have live stitches but we’re not quite ready to get started. You could start knitting now but you’d end up with a flap that was only attached to your sock at one end, and you then have to stitch/graft it toyour sock on 3 sides.

Boring! Especially when there’s a sneaky and fairly easy way to knit so that your heel flap is joined to your sock at the sides.

If you look back at the diagram from MT’s book, you’ll notice that she has 3 needles in play, 2 holding gusset stitches. Basically, you need to pick up stitches for the gussets. You can use the same method I used above with a long tail of yarn and a crochet hook. Or you can do as I did and find the existing gusset stitches and just slide your needle through them.

It’s not as pretty but it’s quick and gets the job done. When I was finished I had: 38 stitches on the first needle (the heel flap stitches) and 16 stitches on EACH of the gusset needles. Remember you have TWO gussets, one on each side of the heel flap.

You now should have all the stitches you need to start knitting.

Step Two

Now comes the easy bit. You’re going to re-knit the heel flap – the bit that comes down over your Achilles tendon – joining it to the sock at the sides as you go.

Look back at the pattern you used to knit your sock in the first place. In my case Froot Loops from Knitty. If it uses a fancy stitch for the heel, double check your numbers to make sure they fit any special requirements for that stitch. E.g. my pattern calls for a repeat of 7 stitchs repeated 4 times (28 stitches) plus 1 slipped stitch at the start (29 stitches) plus 2 extra stitches on the end (31). I had 38 stitches on my needle, which works out beautifully, just adding in an extra repeat of the main pattern. Does that make sense?

Once you’re happy with your numbers, just start knitting the heel flap as per your pattern instructions, up until the last stitch.

When you get to the last stitch on your main needle, you’re going to knit (or purl) it together with the next gusset stitch.

You are basically going to be working back and forth across your main needle, combining in one stitch from the gusset at the end, each time.

This has the effect of keeping the numbers of stitches on your main needle the same, while binding your heel flap to the sock.

Keep working back and forth like this until you have integrated ALL your gusset stitches on both sides. What you end up with at this point should look like this:

Step Three

Now, you’re going to turn the heel. Use the instructions from your pattern. That’s all you have to do, you have no gusset stitches left to combine, you just need to make the little roundy pocket for your heel. Do whatever it says in your pattern.

I used Sock Innovation to calculate my numbers for my short rows – Cookie A. includes a very handy chart in the introductory chapters which gives you the magic numbers you need.

Step Four

You’re now ready to bind your new heel to the sole of your sock. There are a number of methods you COULD use to do this. Kitchener’s stitch would work well, you could pick up stitches across the sole of the foot and do a three needle bind off.

Or you could do what I did and cast off your stitches and just sew the flap down.

Bish, bosh, done.

Weave in any loose ends and check the rest of your sock for holes or weak places. I’ve learned the hard way that once the wool starts to thin it won’t be long before it will just dissolve, leaving you sad and holey.

Once all your mending is done, put on your new old socks and dance around, feeling smug and thrifty! With your slippers on, obviously.

And there you have it.

I hope that was reasonably clear and at least a little bit useful. MT’s condenses all this into about two sentences and it took me ages to figure out the hows and wherefores of it all and I thought there may well be someone else out there facing the heart break of trying to figure out how to salvage the wreckage of a pair of beloved socks.

Do please let me know if it’s useful or not, or if there’s anything that is completely bamboozling. I’ve never written a knitting tutorial before and have found it a lot more difficult than the sewing ones.

Sarah